-

PHONE

+39 0522 964949 -

PRICE LIST

Ask for the price list

We have extended the range of available processes by introducing premilled blanks suited to the majority of implant connections.

Dental technicians are often asked by dentists to design one or more custom abutments that can be connected even to the less commonly-used implants.

Proxera has agreements in place with the majority of manufacturers, allowing it to provide dental technicians with the possibility of obtaining custom abutments for almost all types of implant connections.

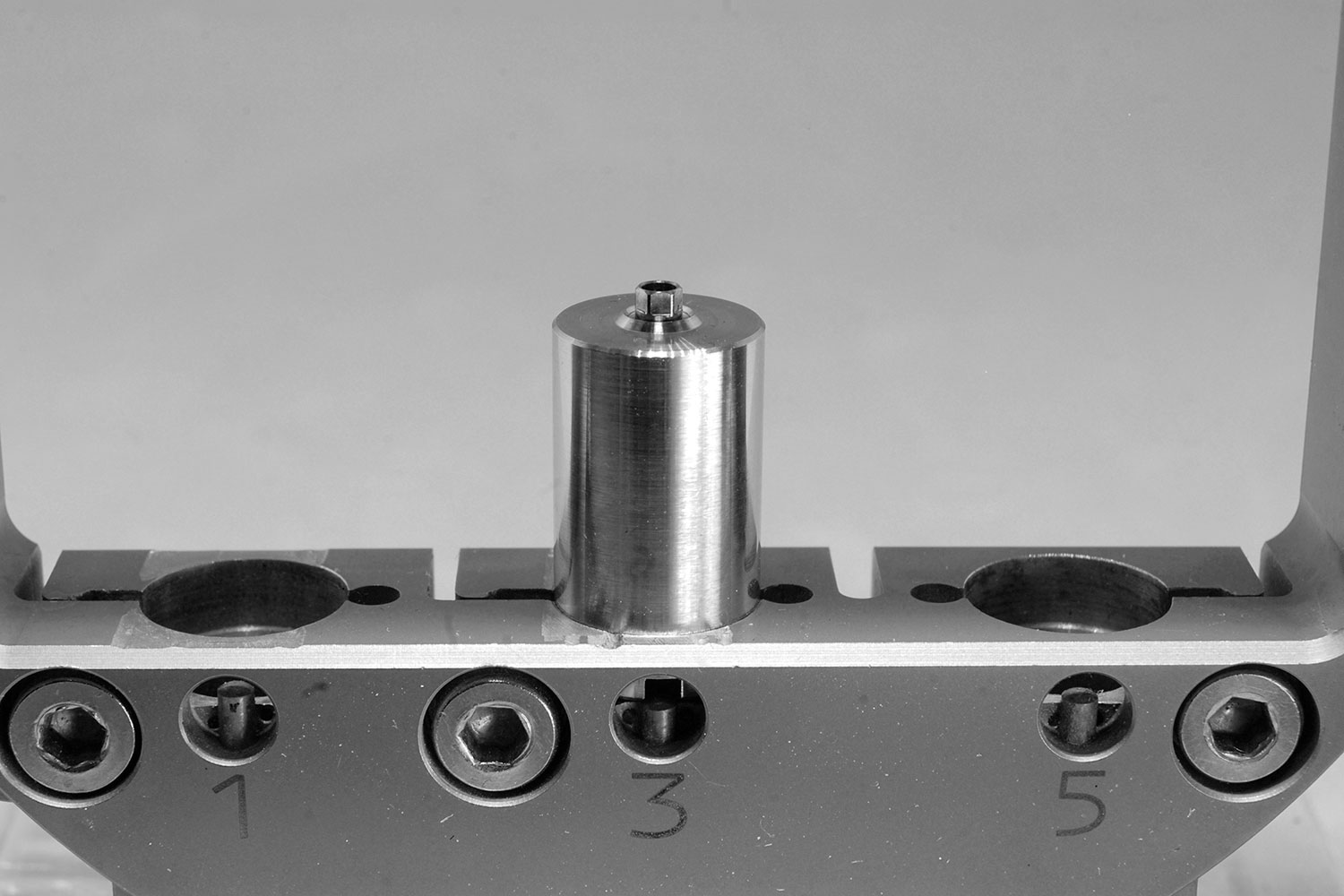

In the dental technology field, a premilled blank is a semi-finished product made of Cobalt Chrome or Titanium on which the manufacturer has pre-machined the implant connection with perfect mechanical precision.

The geometry of the connection differs depending on the implant and, usually, it is the property of the manufacturer who, therefore, supplies semi-finished products that allow the dental technician to concentrate on the anatomy of the restoration with the certainty of a perfect coupling between the abutment and the implant inserted.

Premilled blanks therefore allow a faithful replication of the CAD/CAM project, relying on the utmost industrial precision of the machine tool, even for the less commonly-used connections.

An abutment is a delicate element that is positioned between the capsule and the implant when it is necessary to replace a single missing tooth or when several elements are involved and the dentists opts for a bridge.

The purpose of an abutment is both to provide structural sturdiness, as it is screwed to the implant, and to act as the base onto which the crown will be cemented.

The company that manufactures the implants supplied to dentists usually manufactures standard abutments - without an anatomical design - that can be inserted onto the implant connection, which can generally suit most cases.

However, when standard elements are used, it is often the case that such a wide array of adaptation options is not the ideal solution: standard abutments usually have a very narrow neck that, in addition to not ensuring a perfect aesthetic result, tends to rest on the gum in an unnatural manner, consequently exposing the area to the risk of peri-implantitis.

Custom abutments follow the contour of the gum perfectly, resulting in a solution that ensures easier cleaning, better overall health and duration of the implant, and also an aesthetic result that is much closer to that of natural teeth.

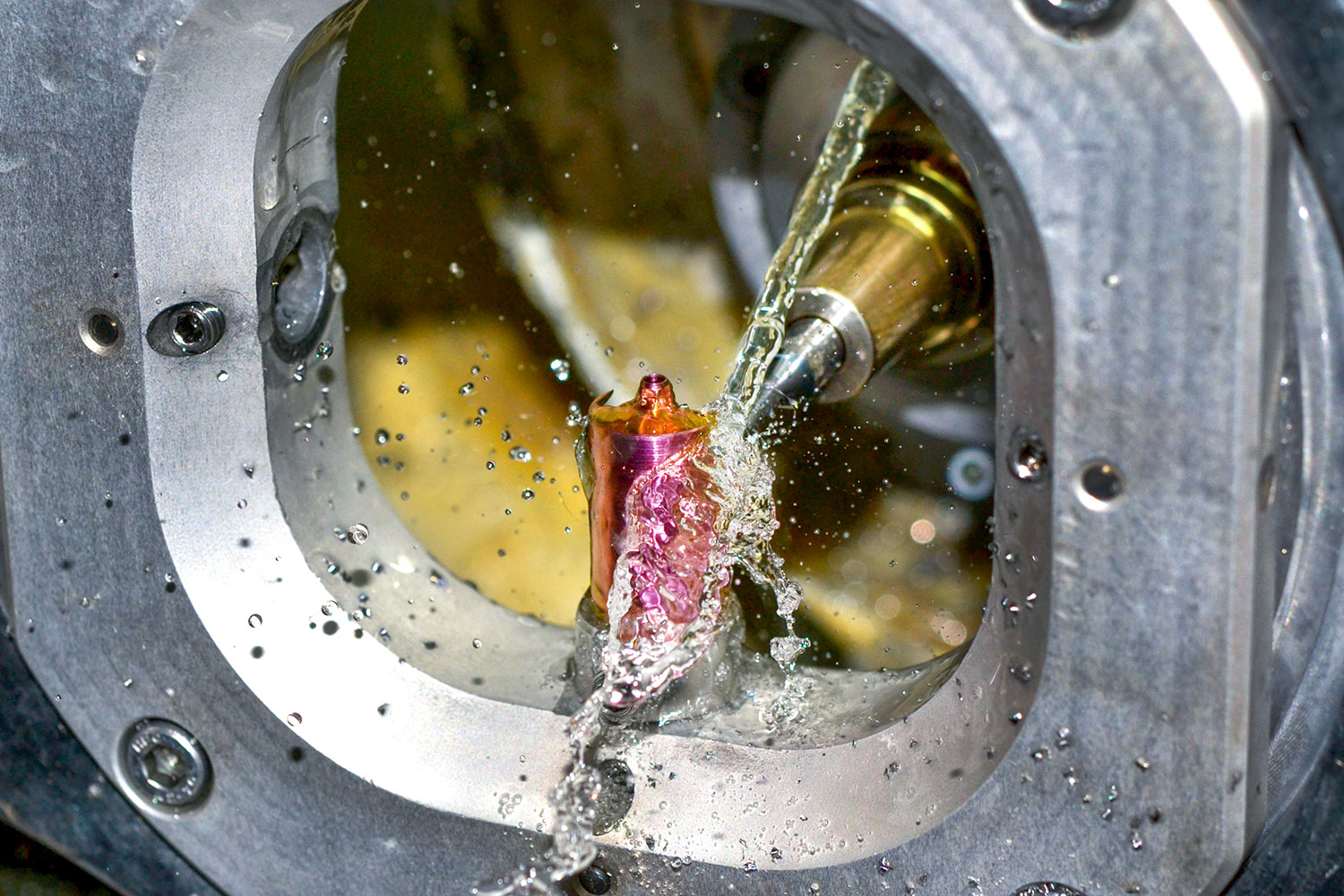

CNC milling machines suitable for processing hard metals such as Cobalt Chrome or Titanium are not usually feasible options for dental laboratories due to the costs involved, which are anything but negligible, the training required to use them, the mandatory maintenance involved, and the procedures to be followed for the disposal of used liquids and shavings.

When machining a premilled blank, it is also necessary to contact the specific implant manufacturer, purchase the unmachined block and wait for it to be delivered.

Proxera provides efficient industrial Röders RXP500DS 5 axis machining centres equipped with a 24 pallet loader that operate continuously, 7 days a week, and it already has agreements in place with the majority of manufacturers, allowing it to receive premilled blanks for every implant connection with reduced delivery times.

All dental technicians have to do is to design the custom abutment and send us the file: we will take care of the rest.

© Copyright 2021. All Rights Reserved. Proxera S.r.l. - Via Marchesi, 1 - 42022 Boretto (RE)

C.F. / P.IVA / Reg. Imp. RE 02741880351- R.E.A. 309389- Cap. Soc. € 30.000,00 i.v.a.

Information on the processing of personal data | General terms of sales | Cookies Policy